Industry Dynamics

Seven digital transformation trends in the logistics industry and how to deal with them

Counts:196 Time: 22-05-21 From: Suzhou Teknect Engineering Co., Ltd.As end customer needs become more diverse and personalized, and the number of suppliers grows every year, so the demand for logistics from customers is also increasing. Now, both B2B and B2C companies need to compete to provide maximum satisfaction, and now, this trend is becoming more and more pronounced.

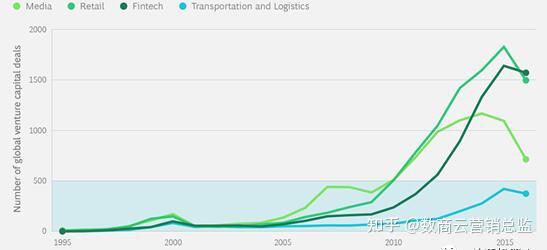

In the next five years, the digitalization of the logistics industry will increase significantly. Until recently, however, the adoption of the latest digital technologies in the logistics industry was slow. Compared to other industries, the digitization of logistics organizations is still significantly behind other industries (see chart below).

Many technology disruptors are challenging the livelihoods of logistics companies. With strong VC capital, some "reckless teenagers" composed of startups, from peers, from technical service providers, from customers, to savvy competitors, they have incubated a completely new business model, and the competition in the logistics circle is extremely fierce.

One thing these threats have in common is that most of the competition is digitally rolling over the industry. These integrators have taken market share from traditional logistics organizations by providing more streamlined end-to-end services, and of course, traditional logistics service providers themselves are also crossing the river in digital services and operations, and it is difficult for today's logistics industry to avoid the bayonet in digital competition.

Digitalization is applied to the logistics industry

With the help of modern IoT, artificial intelligence, cloud technology, blockchain, process automation RPA, and other major data innovations, the logistics industry has the opportunity to revolutionize. It is clear that the industry is in great need of digital transformation. As driverless technology expands and vehicles innovate, the logistics industry must evaluate any new technologies and adapt to them. According to the Digital Transformation Spending in Logistics Market report, digital transformation spending in the global logistics market is expected to achieve a compound annual growth rate of 109.7% by 2026, successfully achieving $94.97 billion.

7 key technology trends in logistics digitalization

As end customer needs become more diverse and personalized, and the number of suppliers grows every year, so the demand for logistics from customers is also increasing. Now, both B2B and B2C companies need to compete to provide maximum satisfaction, and now, this trend is becoming more and more pronounced.

Let's look at the factors of successful digitalization and the key points in building a digital strategy. It defines seven key technology trends for successful digitalization of logistics.

1. Electronic waybill

Electronic Air Waybill (e-AWB) is an initiative for the digitalization of the industry. It is the standard digital version of the current air waybill and is followed from the shipper to the shipment.

e-AWB greatly improves the efficiency of tracking and processing cargo data, while also increasing transparency, improving safety and reducing costs and delays. So far, it has gained widespread acceptance, with the International Air Transport Association (IATA) announcing the e-AWB's default contract of carriage earlier this year. Major airlines such as Lufthansa and Emirates have already implemented the scheme. Companies like Delta And One are expected to follow soon, meaning the industry's adoption rate is expected to reach 80 percent by 2020.

2. Artificial intelligence and machine learning

The potential of AI and machine learning in logistics is enormous: supply chains can be a real gold mine for structured and unstructured data, and by leveraging and analyzing data, identifying patterns, and gaining insight into every link in the availability chain, logistics companies can significantly transform operations.

Machine learning can help companies discover patterns in supply chain data in algorithms that can identify the most important factors that affect the success of their supply networks while continually learning. These models can relate to inventory levels, supplier quality, forecasted demand, production planning, transportation management, etc., and provide companies with knowledge and insights to reduce freight costs, improve supplier performance, and minimize supplier risk.

3. Cloud logistics

Cloud logistics is moving forward at a rapid pace, with 60 percent of logistics providers having previously used cloud services and another 30 percent wanting to do so. As data moves to the cloud, logistics IT services are paid on demand for frequency of use, suggesting that smaller businesses don't have to struggle with the overall IT structure and only pay for the services they use when they need to.

4. Internet of Things (IoT)

The Internet of Things will become a game changer in the future. Combined with state-of-the-art availability and sensors, it can correlate any item to the network for all purposes, no matter where it is, which means full visibility and traceability from shipper to shipper. No wonder it's expected to bring $1.9 trillion in revenue to the logistics industry.

IoT-connected sensors will monitor the temperature and humidity of sensitive goods such as food and medicine. Near Field Communication (NFC) tags will provide product certification through smartphone ports, preventing forgery and theft.

5. Blockchain

The far away but with great potential is blockchain. Blockchain technology extends immediacy, timeliness, and accessibility by providing reciprocal, timely data instructions for each member of the chain. By reducing complexity and breaking down trade barriers, this could lead to a 5% increase in global GDP and a 15% increase in global trade.

Since all parties involved can track the progress and status of the product at the same time, the supply chain will become more efficient, more timely, and more lucid.

6. Self-driving cars

Until now, automated forklifts are very common in today's factories, warehouses, terminals, ports, and other areas with elegant environments. And we'll soon see self-driving trucks on the roads, transporting goods to be unloaded by automatic forklifts and putting them into warehouses via automatic conveyor belts and robotic arms.

Vehicle-to-vehicle communication will cause self-driving trucks to line up, a bit like geese in the sky, to reduce costs. Improving the resistance generated by deceleration and acceleration means using less fuel, which accounts for 30% of the truck's total operating costs.

7. RPA's Commitment

According to the Digital Journal, RPA is "the use of software with artificial intelligence (AI) and machine learning capabilities to handle high-volume, repeatable tasks that previously required human execution." "These tasks may include the maintenance of records and transactions, calculations and queries. RPA can save a lot of money and efficiency, and improve accuracy, and while it doesn't necessarily reduce the number of employees in a company, it frees up employees to do more creative, fun work that increases company value.

RPA is promising for the logistics industry, especially at present, which relies on a lot of paperwork and a lot of manually entered data to operate and conduct daily transportation transactions. Generating and processing the right document is time-consuming and monotonous work that has become a ripe time for RPA outbreaks.

The potential of RPA will be fully realized as processes are standardized and become more complex through the use of cognitive or intelligent automation that can handle unstructured and structured data. Employees no longer need to find information to enter it into the system, greatly eliminating the need for manual intervention.

Previously, much of the work was done manually by the operator. However, unlike human operators, this software robot can work 24/7 and can be constantly checked and updated. RPA greatly reduces the time spent on manual processing. It also enables robust process control and completely accurate output – all of which provide greater visibility to the end customer.

Facing digital challenges

Logistics companies, from small family businesses to franchise networks and multinational corporations, all belong to similar delivery chains, but differences in systems between them can lead to friction and tracking of processes that are challenging, and this lack of connectivity will inevitably hit businesses that do not embrace digital transformation. The three key core challenges we see are:

1. Accelerate cloud-based technologies

Logistics companies have always distrusted cloud-based solutions and therefore adapt to IT infrastructure at a slow pace, putting them at a disadvantage to new or more agile technological innovations. Cloud solutions provide flexibility, resources and applications, and services to diversify while using real-time information to improve business efficiency. Logistics companies need to recognize that the same products cannot be developed internally to achieve the same agility and deliver the speed of delivery needed to remain competitive.

2. Data quality and data cleansing

Data quality in logistics is another long-standing problem, especially when data responsibilities are left to low-wage employees, where datasets often lack consistency or reliability. Improvements in system connectivity can lead to automated data collection, including data collection from IoT devices, which frees employees from manual data management, allowing inputs to be properly validated using ARTIFICIAL intelligence to clean up data and complete missing or incomplete parts.

3. Coordination and modernization of source systems

Many of the major source systems, such as transportation management systems, warehouse management systems, and financial systems, are legacy systems that have not yet evolved to support standards for digitization and big data. Many of these systems only support older data exchange protocol standards and lack open APIs that limit opportunities for growth and data exchange with industry partners. To take full advantage of the development of big data, logistics companies need to invest in reviewing, replacing, and coordinating source systems.

Whether we like it or not, all of these technologies will come along. But that doesn't mean we can sit back and wait for them to happen. Logistics operations need to actively work with technology companies to implement these solutions. Outsourcing is often the easiest way to achieve flexible on-demand services instead of trying to build a large in-house IT infrastructure.

It is not that we can choose to do so, but that we must do so. If we don't take the initiative to face the challenges posed by digitalization, we risk being defeated by new, more agile disruptors.

Digital solutions for logistics

The grand blueprint for transformation relies on three key digital initiatives: developing new business models and products, digitizing core operations, and building a strong internal digital foundation. A successful model of logistics organization requires some input. Include:

1. Develop new business models

o New digital platform. Building a robust new platform will help eliminate supply chain inefficiencies, address issues related to underutilization of assets, improve demand-supply matching, and increase visibility and connectivity across the system.

o Advanced analysis. Powerful data-driven solutions enable you to create new analytics tools that can be sold to customers to help them optimize operations and efficiency.

O Control tower. Provide solutions that improve operational visibility and connectivity between previously isolated systems, enabling stakeholders to connect more seamlessly throughout the supply chain.

2. Digital core operations

o Advanced analysis. Similar to the benefits of providing new analytical tools, logistics organizations themselves can use advanced analytics to optimize operations in the consolidation of pricing, routing, and partially loaded goods.

o Customer experience. Not only does the digital front end provide customers with a convenient one-stop shopping experience, but it also improves visibility into internal operations and automates previous manual processes.

o Process automation. Increasing the automation of core internal business processes can help alleviate labor-intensive logistics operations, such as digitizing procurement through E-auctions.

o Equipment data. Digital monitoring of equipment health can lead to more effective predictive maintenance.

Ø Next generation solution. Looking ahead to future operational improvements through robotics, artificial intelligence, and even augmented reality can help further improve the operational efficiency of logistics organizations in distribution, warehousing, picking, and packaging.

3. Build a robust internal digital organization

o Talent. Logistics companies must actively target and attract smart digital talent to be competitive, maintain efficiency, develop new areas and deliver on value promises to customers.

o System. The benefit of providing digitalization throughout the logistics organization is to help rationalize investments in more flexible technology systems throughout the value chain.

o Agile. In solution development, logistics issues need to be agile to maintain a digital pace and maximize its strengths.

ENGLISH

ENGLISH  简体中文

简体中文