Intelligent Forklift Management System

Forklift telematics, Forklift Safety

Only qualified and authorized personnel can operate the designated forklift truck, and the operational efficiency data of each operator are automatically recorded and analyzed.

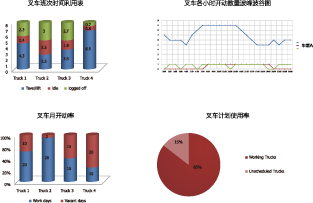

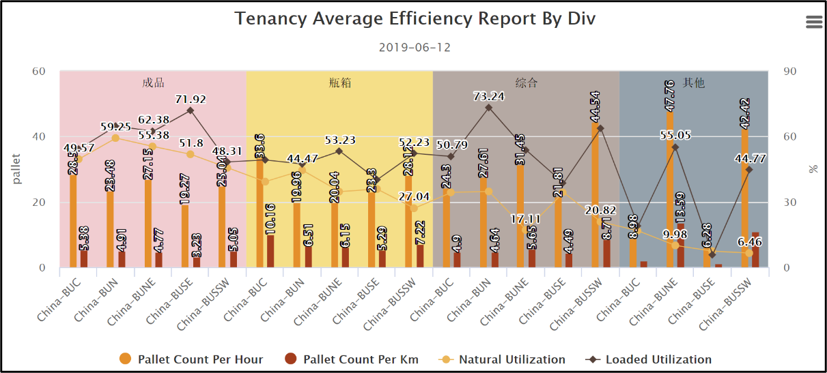

The analysis of the utilization ratio of forklift truck provides a reasonable basis for increasing or decreasing the number of vehicles or internal allocation of vehicles, and maintains the good state of the whole fleet through timely maintenance management and charging management of forklift truck.

Every collision beyond the user's tolerance limit will be recorded by the operator, which can effectively regulate the operator's driving behavior and reduce the safety accidents caused by forklift collision.

Forklift Telematics, Industrial vehicle management system

Forklift Truck Management System

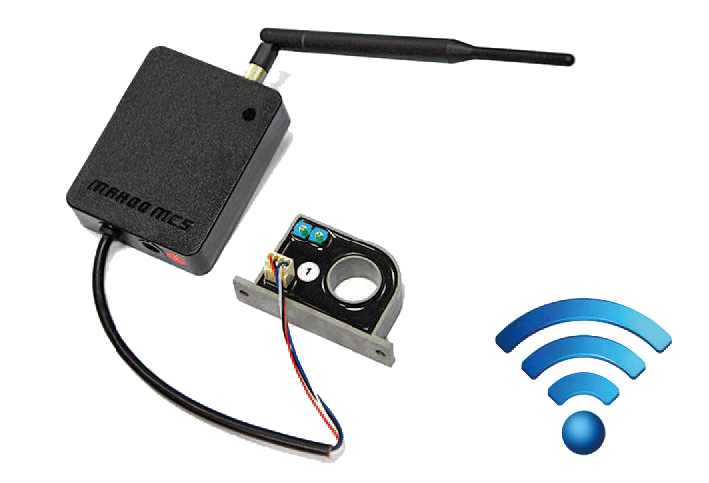

Through APP, the administrator sets the password to the operator according to the task or training situation (the validity period can be set), and the operator enters the password to start the forklift automatically.

Forklift Impact Monitor, forklift monitoring system

The Teknect fleet management module contains collision sensors, which are placed horizontally inside the vehicle body to sense collision forces from all directions of the forklift truck.

The limit value of collision force can be calibrated according to customer working conditions.

After the collision occurs, the management module automatically sends out an alarm and can automatically lock the forklift truck according to the settings.

Through collision monitoring, forklift collision events can be effectively reduced.

Utilization Analysis, industrial truck management system

The Teknect management system can obtain log-in, actual working time and standby time of the forklift, so as to analyze the utilization rate of the forklift, and provide data support for managers to allocate the number of forklifts used.

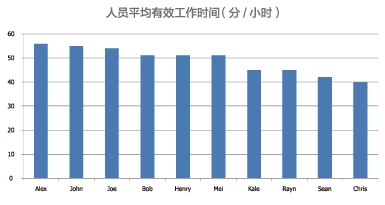

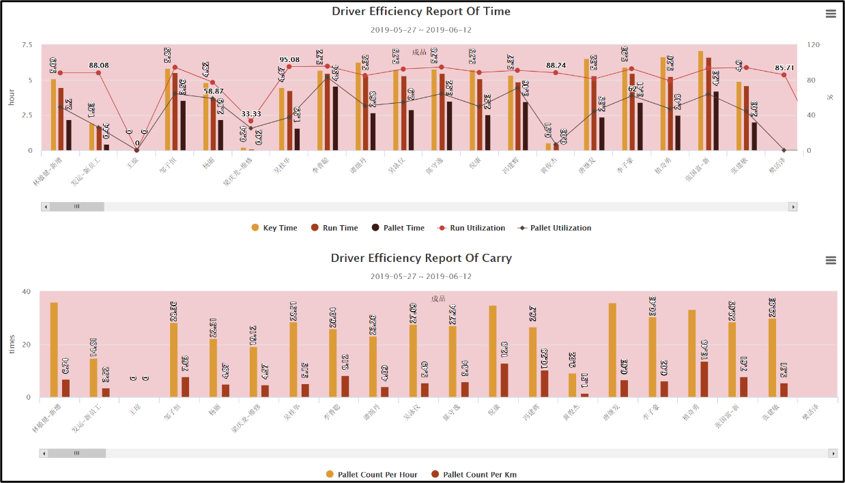

Analysis of Personnel Efficiency Lift truck telematics

Operators'actual effective working hours per shift, i.e. work efficiency, are displayed in the order from high to low or from low to high, and various reports are automatically pushed to managers' mailboxes.

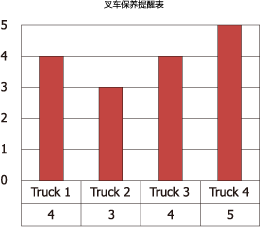

Forklift fleet management system

The system can set different maintenance intervals for each type of vehicle. The maintenance intervals can be timed by forklift start time or calendar time.

The system has automatic reminder function of near maintenance and provides report forms for easy management.

Charge Management, forklift telemetry system

Real-time monitoring of vehicle power consumption reminds drivers to charge in time to ensure adequate vehicle power

Recording the power and fuel information of each shift prompts the driver to ensure normal charging and prevents frequent charging from affecting the battery.

The first battery can be equipped with sensors to monitor the battery voltage, current, electricity, temperature, battery level and other data.

* Battery management system can be purchased separately

ENGLISH

ENGLISH  简体中文

简体中文