Industry Dynamics

How to Operate a Forklift: Pre-Operation, Traveling, Load Handling, and Maintenance

Counts:536 Time: 21-07-12 From: Suzhou Teknect Engineering Co., Ltd.In this article, we set out to explain how to operate a forklift. If you’ve been wanting to learn how to drive a forklift, then this is a great starting point for you.

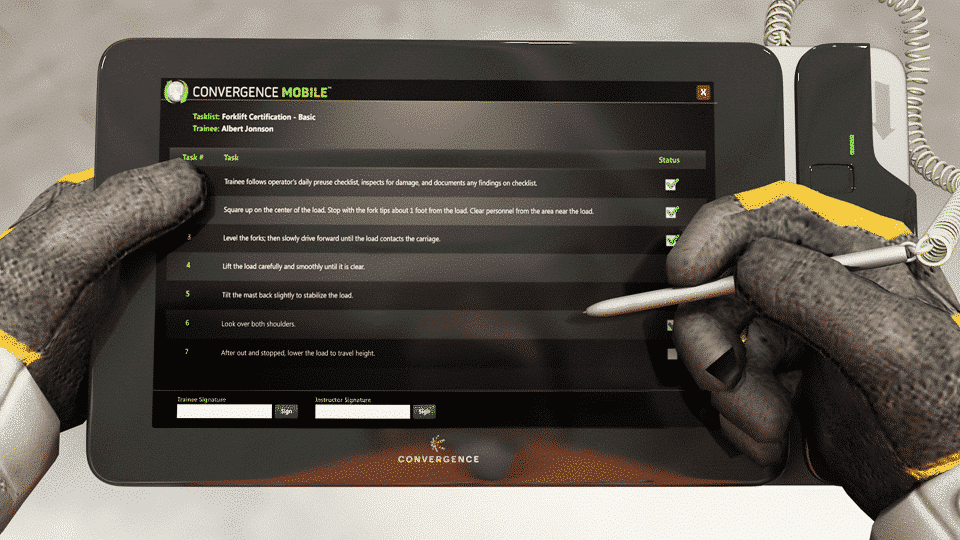

You’ll learn valuable and helpful information in this article, but please know that you won’t know how to drive a forklift safely just as a result of reading this article. That takes more extensive forklift operator training, including demonstrations from a skilled instructor, practice forklift operation by you, and a forklift operator skill demonstration evaluated by your instructor.

But, as we said, if you’re looking for a great and helpful 101-level introduction of how to operate a forklift, then you’re in the right place.

How to Operate a Forklift: Pre-Operation, Traveling and Maneuvering, and Load Handling

We’ll break down instruction on how to drive and operate a forklift into three sections:

- Pre-operation, including pre-operation inspections

- Traveling and maneuvering the forklift

- Handling loads with the forklift

As you’ll see, each of the three sections will be broken down into instructions for smaller tasks involved in learning how to drive a forklift.

Remember that before anyone operates a forklift, they must receive proper forklift safety training. OSHA details the specifics for that in 1910.178(l) and we have a separate article on forklift operator training requirements as well.

Forklift Pre-Operation Duties

Before you can operate a forklift, you’re going to need to:

- Perform pre-operation inspections, which vary depending on the type of forklift

- Mount the forklift

- Start the forklift

- Perform operational inspections with the engine running

Instructions for performing each of these steps of operating a forklift are provided below.

This should go without saying, but we’ll say it anyway: if a forklift has been taken to service because it’s defective, needs repair, or is in any other way unsafe, never return it to service until the problem has been resolved.

Pre-Operational Forklift Inspection

In 29 CFR 1910.178(g)(7), OSHA requires all forklifts be examined at least once a day before they are placed into service. If a forklift is used around the clock, then inspections must occur after every shift.

The forklift operator should preform two inspections:

- Pre-operational visual inspection with key off

- Operational inspection with engine running

We’ll cover both inspections in this section, starting with the pre-operational inspection.

If the forklift operator determines that the forklift needs repair or servicing as a result of the inspection(s), the forklift must be immediately removed from service.

General Pre-Operational Inspection Items

Before the forklift is turned on, visually inspect the following:

- Oil level

- Water level

- Hydraulic fluid level

- Hydraulic hoses (look for leaks, cracks, or any other defects)

- Mast chains (look for cracks, breaks, or any other defects). Use a stick or similar device to check the chain tension. The forklift operator should never place a hand into the mast.

- Tires, including condition and pressure (be sure to inspect for cuts and gouges)

- Forks (check the condition, including the top clip retaining pin and heel

- Loaded backrest extension

- Finger guards

- Safety decals and nameplates (make sure they are all in place and legible; check that the information on the nameplate matches the model and service numbers and attachments)

- Operator manual (make sure it’s there on the truck and that it’s legible and complete–no missing or torn pages, etc.)

- Operator compartment (check for debris, grease, etc.)

- Safety belt and all other safety devices (make sure they’re all working properly)

Pre-Operational Inspections for Electric Forklifts

If you have an electric-powered forklift, check these items during the pre-operation inspection in addition to the items on the “general” list:

- Cables and connectors (look for frayed, exposed, or otherwise damaged wires)

- Battery restraints

- Electrolyte levels (always use proper personal protective equipment, such as a face shield, rubber apron, and rubber gloves, when checking the electrolyte level)

- Hood latch

Pre-Operational Inspections for Internal Combustion Forklifts

If you have a forklift powered by an internal-combustion engine, check these items during the pre-operation inspection in addition to the items on the “general” list:

- The liquid propane tank (ensure it’s properly mounted; check for dents and cracks; check to make sure it fits within the profile of the tank)

- Pressure relief valve (make sure it’s pointing up)

- Hoses

- Connectors

- Tank restraint brackets

- Any leaks

Remember to always use proper personal protective equipment, such as a face shield, long sleeves, and gauntlet gloves, when making these inspections

Per-Operational Inspections for Liquid Propane Forklifts

If you have a forklift powered with liquid propane, check these items during the pre-operation inspection in addition to the items on the “general” list:

- Engine oil

- Brake reservoir

- Engine coolant

- Air filter

- Belts and hoses

- Radiator

- Hood latch

Free Downloadable Forklift Inspection Checklists

We’ve even made some handy Forklift Inspection Checklists for you to download. Nice, huh?

Mounting the Forklift

People frequently get hurt while attempting to mount the forklift they’ll operate. In particular, hazards include:

- Hitting your head on the overhead cage

- Slipping, tripping, and falling, especially when feet slip off the step

Here are some ways to avoid these hazards:

- Make sure your hands are clean, dry, and empty when mounting the forklift

- Wear appropriate shoes or boots that avoid skids

- Check your shoes for grease or anything else slippery

- Grab the handhold and get a good trip. Don’t grab the steering wheel as a way to mount the forklift–the steering wheel may move, causing you to lose your balance

- Be careful with your footing at all times; be aware of what you’re doing, do it slowly, and be intentional

- Pull your body up into the forklift-don’t jump

Starting the Forklift

Don’t try to start the forklift before you’ve completed the pre-operational inspection. Once that’s done, start the forklift and then prepare to complete the operational forklift inspection before driving off.

Operational Forklift Inspection

After the pre-operational inspection (with key off) is complete and you’ve mounted the forklift, it’s time for a operational forklift inspection.

You’ll conduct this second inspection with the engine running. During the operational inspection, check:

- Accelerator linkage

- Inch control (if present)

- Brakes

- Steering

- Drive control, including both forward and reverse

- Tilt control, including forward and back

- Hoist and lowering control

- Attachment control

- Horn

- Lights

- Back-up alarm (if present)

- Hour meter

In addition to all of the above, observe for unusual noises or vibrations. If you detect any, report them immediately.

Traveling and Maneuvering the Forklift

In this next section of our instructions on how to drive a forklift, we’re going to cover instructions for traveling on and maneuvering the forklift.

Many people think that operating a forklift is simple and basically like driving a car. But in fact, driving a forklift is very much different than operating a car, and that’s one of many things you should know before you operate the truck.

Visibility Concerns While Operating the Forklift

Operating a forklift with blocked or partially blocked visibility increases the chances of an accident.

Impaired visibility can lead to hazards such as:

- Collisions

- Falling load

- Having the forklift fall off a loading dock

- Striking or crushing pedestrians

Because none of that is good and we want to avoid all of it, do everything possible to make sure visibility is entirely unblocked or blocked as little as possible before operating. Here are some requirements and recommendations:

- Keep a clear view

- Look in all directions around you before you begin

- When traveling, always look in the direction of travel. This includes looking behind you when operating in reverse

- Use spotters, rear view mirrors, and/or other aids to increase visibility whenever possible

- When possible, use concave mirrors when entering buildings or aisles and/or when approaching corners or other blind spots

- If lighting is dim (less than two lumens per square feet), use headlights

- Use headlights when operating at night, outdoors, and/or in any area where additional lighting would improve quality

- Drive slowly into and out of warehouses or other buildings. Moving from a bright to a dark area, or from dark to bright, can temporarily disrupt visbility.

- Be cautious on loading docks and stay away from edges, which can be hard to see

- Slow down and sound the horn at cross aisles and other locations where vision can be obstructed

In addition, consider adding the following at the work area to decrease hazards related to limited visibility:

- Add physical barriers such as ramps, raised concrete staging areas and heavy-gauge safety chain in front of loading dock openings.

- Use protective guard rails

- Add a “warning track” of yellow floor paint near dock openings

Beginning to Drive the Forklift

Before you begin to move the forklift, make sure your way is clear by looking in your direction of traffic. Sound your horn and/or use a spotter if your vision is obstructed.

Once you’re sure your path is clear, proceed with caution down the path of travel and watch for dangerous curves, blind spots, intersections with pedestrian traffic, and/or any other hazards.

Driving the Forklift at Speed

When you’re driving the forklift at speed, always anticipate and do everything possible to avoid the following potential hazards:

- Tipovers caused by driving too fast

- Collision with pedestrians and obstacles caused by not paying attention and not having time to stop

In short, drive slowly and pay attention.

In addition, follow these requirements and recommended practices:

- Look in the direction of, and keep a clear view of, the path of travel

- Always operate the forklift at a speed that will allow you to stop it in a safe manner

- Slow down when driving on wet or slippery floors

- If the load you’re carrying obstructs your forward view, travel with the load trailing instead

- Slow down and sound the horn at cross aisles and other locations where your view is obstructed

- When turning, always slow down to a safe level and turn the steering wheel in a smooth, sweeping motion

- When driving up or down a grade (or incline), always do so slowly

- When driving up or down a grade in excess of 10 percent, drive a loaded truck with the load upgrade

- Don’t run over loose objects on the path of travel

- Obey and/or observe all posted speed limits and warning signs

Changing the Forklift’s Direction of Travel

Changing directions on a forklift raises hazards. These include:

- Tipover

- Collision with a pedestrian

- Collision with another vehicle

- Collision with an object

To avoid those hazards, follow these requirements and recommendations:

- Always stop completely before changing directions

- Use a horn and/or a warning light to warn pedestrians before and while you operate in reverse

Steering and Turning the Forklift

When you’re steering a forklift, potential hazards include:

- Collisions with pedestrians or objects; this hazard is increased because of the way the rear end (or tail) of a forklift swings out widely to the side opposite the turn

- Colliding with something and then having the load fall

- Tipovers caused by turning too sharply

To avoid these hazards, follow these requirements and recommendations:

- Plan your route in advance and anticipate all turns

- Never turn with the forks elevated

- Never turn on a grade (or incline/decline). Turning on a grade makes the forklift more likely to tipover–even a small grade.

- Reduce speed to safe level when turning

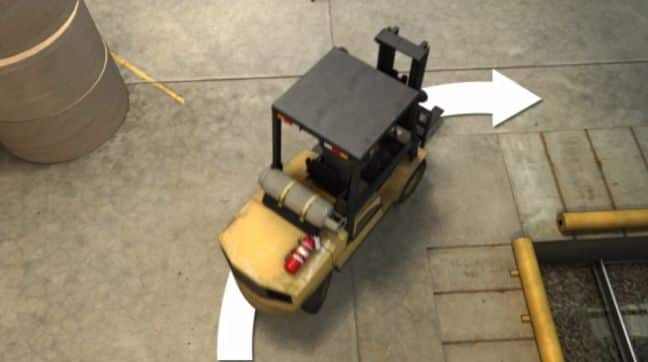

- Use extreme care when making a turn, especially when turning in confined areas or narrow aisles. This is because when a forklift turns a corner, the rear end of the forklift swings out widely in the direction opposite of the turn

- Because the forklift’s tail end swings out widely in the direction opposite of the turn, always start the turn as close as possible to the inside corner

Reversing the Forklift

Reversing a forklift increases the risks of injury and accidents. Hazards involved in reversing the forklift include:

- Striking or crushing pedestrians

- Colliding with another forklift or object

Always use extreme caution when backing up. In addition, follow these requirements and recommendations:

- Keep a clear view in the direction of travel

- Look in the direction of travel. That means looking behind you when driving in reverse.

- Always be aware of limited visibility, and use extra caution when driving in reverse

- Consider using ground guides, rear-view mirrors, spotters, or other aids to increase visibility while operating in reverse

- Consider the noise level in your workplace and the possibility that other workers are wearing hearing protection. Don’t assume that pedestrians or bystanders are able to hear your back-up alarm.

- Always leave lots of room for pedestrians. Remember that you can’t correctly anticipate all of their actions and many pedestrians are not familiar with the operational limits of a forklift.

- Don’t grab the overhead guard when traveling in reverse. This could result in harm to your finger.

Operating the Forklift on Grades (Inclines and/or Declines)

When a forklift is operated on a grade, hazards include:

- Tipover

- Falling load

To reduce these hazards, follow these requirements and recommendations:

- Always drive unloaded forklifts with the forks downgrade

- Never drive a loaded forklift with the load downgrade

- When driving up a ramp, drive loaded forklifts forward with the load upgrade

- When driving down a ramp, drive loaded forklifts in reverse with the load upgrade

- Never turn a forklift while driving on a grade (incline or decline)

Safe Forklift Travel Practices

Forklifts always pose some level of hazards while they’re being operated, including:

- Overturning

- A load that falls

- Striking a person or crushing a person

- Collisions

As a result, always follow these requirements and recommendations while operating a forklift:

- Always look in all directions before beginning to travel

- Always look in the direction of travel while traveling

- If a load on the forks blocks your view of the intended path of travel, travel in reverse.

- Always maintain a safe distance from the forklift ahead of you (about three truck lengths)

- Observe all traffic regulations and posted signs, including plant speed limits

- Keep the forklift under control at all times

- Yield the right of way to ambulances, fire trucks, or other emergency vehicles in emergency situations

- Don’t pass other forklifts (or powered industrial trucks) that are traveling in the same direction while at intersections, blind spots, or at other dangerous locations

- Whenever possible, avoid crossing railroad tracks in a perpendicular direction. Instead, cross them diagonally when possible

- Never park closer than 8 feet from the center of railroad tracks

- Always operate the forklift at a speed that will allow you to stop the forklift safely under all travel conditions

- Never take part in horseplay while driving a forklift and never take part in stunt driving with a forklift

- Slow down while operating on wet or slipper floors

- Properly secure dockboards or bridgeplates before driving a forklift over them. While driving over them, be careful and drive slowly. Never exceed the listed capacity of a dockboard or bridgeplate.

- While driving a forklift, always approach elevators slowly, wait for the elevator car to be properly leveled, and only then and enter the elevator squarely. Once on an elevator, neutralize all controls, shut off the power to the forklift, and set the brakes.

- Do as much as possible to keep forklift traffic patterns separate from pedestrian traffic. When possible, use established pedestrian walkways and strictly enforce their use. Use guard rails and floor markings on pedestrian walkways.

- Never carry a passenger on a forklift

- Keep your arms and legs inside the forklift at all times during operation

- Watch for any surface obstruction; even small ones can knock the load off your truck

- Never drive a forklift up to a person who is in front of a bench or any other fixed object

- Never drive into a position that would lead to a coworker being pinned between the forklift and something else if the forklift jumped forward, the brakes failed, or the wrong lever was pushed

ENGLISH

ENGLISH  简体中文

简体中文