Industry Dynamics

New Lithium Batteries For Your Lift Truck Are The Best Choice

Counts:472 Time: 21-12-19 From: Suzhou Teknect Engineering Co., Ltd.Considering the battery options for your forklifts? Do you know about the advantages of lithium-ion batteries and why the new Lithium batteries for your lift truck are the best choice?

Lead-acid batteries are the more traditional choice for an electric forklift fleet. While lithium-ion systems have been around for roughly 2 decades, they are still a relative newcomer to the game. Thanks to the new technologies used in Li-ion batteries they come with a lot of advantages over lead-acid.

Businesses that want to improve efficiency and create a more productive warehouse need to consider making the switch to lithium-ion power for their lift trucks.

If you’re trying to learn more about the advantages of lithium-ion batteries, look no further. Below we’ll tell you why you should consider using lithium-ion systems for your forklift.

Extended Runtimes

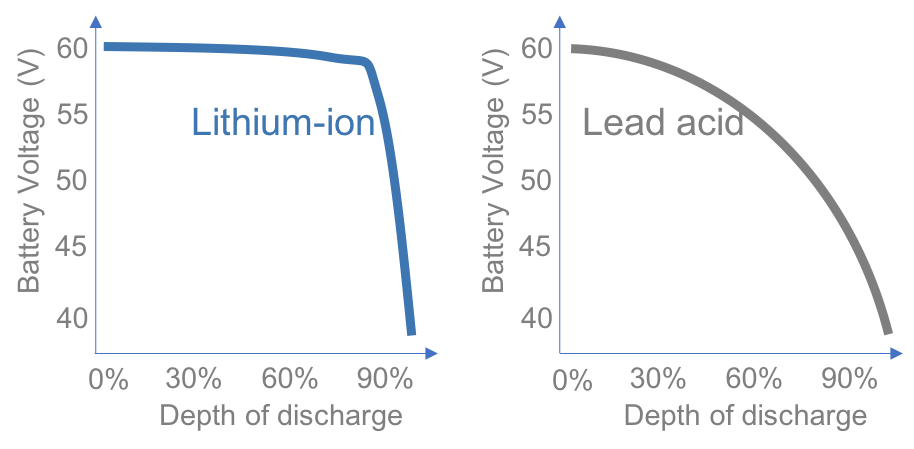

One of the biggest advantages of using lithium-ion in your lift trucks is that they will allow for higher cycle life and longer runtimes. Compared to using traditional lead acid counterparts, lithium-ion systems will last up to 4 times longer. There is no voltage drop through the whole discharge cycle with lithium-ion, so the trucks run and lift as fast at the end of the shift as if they just started. Lead-acid batteries experience a voltage drop and typically lose around 20% of their power during the shift. It’s even worse in a cooler or freezer, where they lose as much as 50%.

The extended life of lithium ion batteries can help a warehouse to always keep functioning seamlessly and to be more productive overall. Your team will be able to get more done and never pause for charging or changing a battery. After all, uptime is the one most important KPI in the material handling industry!

Superior Charging Capabilities

Another great thing about lithium-ion technology is that it also allows for quick and easy charging compared to the lead-acid alternative.

Lithium-ion systems can be charged from ZERO to FULL in just under 2 hours. There is no “memory effect” and it is recommended that you charge your Li-ion forklift batteries any time it’s not in use. This means that a dead battery won’t slow things down, ever.

Li ion batteries are also more efficient than lead-acid. Lead acid batteries can experience heavy degradation if they are being charged too often. However, lithium-ion batteries will stay in great shape regardless of how often they’re charged or what the depth of discharge is. This is true for booth any new battery or the one that has been used for up to 5 years in your operations!

Eliminates Need For Maintenance

A major drawback of lead-acid batteries is that they require quite a bit of maintenance. Watering will be required daily and acid spills will happen. This typically increases labor costs since it takes time and energy to keep them maintained and changed during each shift.

On the other hand, lithium ion forklift batteries require zero maintenance. As a result, using a Li-ion power source instead can reduce costs and save time in your warehouse. It can also reduce labor needs, allowing your workers to focus less on material handling equipment and more on more important tasks in your business instead.

Safer For Workers

While there are many safety hazards in a warehouse environment, forklifts pose one of the biggest threats. This is especially true for trucks that use different types of lead-acid systems. Taking a heavy battery out of the truck to replace it with a freshly charged one every shift increases the risk of injury and equipment damage. Sulfuric acid spills can prove to be a hazard for your workplace and always have the potential to cause harm to employees.

Fortunately, the lithium-ion power source will be safer for your workers and come with automated safeguards that will provide extra protection. With lithium-ion batteries, there is no need to change the battery in the truck, and no risk of acid spills. Since there is no gassing during the charging process, these batteries also won’t emit dangerous hydrogen / sulfuric gas fumes into your work environment.

Additionally, with lithium-ion technology, the disposal will occur much less often and will be extremely easy. When you purchase through OneCharge, we’ll collect it from you once it has reached the end of its useful life. We’ll disassemble the battery, recycle the metal case, dispose of the electronics and send the cells back to the manufacturer for repurposing or disposal and provide you with the documentation to prove disposal was compliant with all applicable regulations.

In many cases, the cells from the battery will be repurposed to serve other applications for years before recycling.

No Battery Room Required

Another advantage of using lithium-ion batteries is that you’ll eliminate the need for the dedicated storage and maintenance room in your warehouse.

Lead-acid systems require the installation of a battery room, where they will be stored and charged when not in use. While charging, these batteries will emit dangerous hydrogen / sulfuric gas fumes (gassing), so the room will need to be well-ventilated and kept cool which adds significantly to operating costs.

When using lithium-ion systems, on the other hand, you’ll only need one battery per truck. Since there is no gassing problem, and opportunity charging can be done almost anywhere, there is no need for an expensive ventilated and air-conditioned storage room. You’ll no longer need to worry about storing or charging spare batteries in a special room. In fact, with a lithium power source, you can look for the most appropriate places to put chargers throughout your facility, to encourage drivers to put the forklift on charge when not in use. This will lower costs and increase uptime.

Ultimately, this means that you’ll be able to return that square footage to your warehouse for storage or production or anything that makes the company money.

Better For the Environment

If you want your warehouse to be more environmentally friendly, choosing to use lithium ion technology for your lift truck fleet is a great choice. Lithium-ion systems offer several improvements over lead-acid batteries. They’re less likely to cause damage to your warehouse, your workers, and the environment.

One of the reasons for this is because lithium-ion batteries are 30% more energy efficient than their lead-acid alternatives. By using lithium-ion you’ll reduce energy consumption in your workplace. This can help the environment and will also reduce costs and carbon footprint. If your company has an internal mandate to reduce its carbon footprint, switching to Lithium power is a great way to help achieve that goal.

Acid spills can also lead to environmental harm when dealing with lead-acid. Lead-acid systems can also emit hydrogen / sulfuric gas into the air during charging.

Li-ion batteries, on the other hand, don’t contain toxic substances or emit harmful gasses. This means that they’ll be much safer for both the environment and for employees.

Saves Money

Using lithium-ion batteries instead of lead-acid batteries can also help a business to save money. While they will cost more upfront, the advantages are well worth the cost and will save your business money over time. Once you do the calculations, you’ll see that the total cost of ownership is much lower (usually in the order of 20%-40%) than with lead-acid packs. This is especially true for companies with multi-shift operations, where the ROI is often positive within the first year.

Energy consumption will be lower when using lithium-ion batteries.

As we’ve mentioned earlier, there is no daily maintenance of Li-ion batteries. This means you’ll also be spending considerably less money on labor. Daily watering, cleanup of the battery & lift compartment in addition to swapping out the lead-acid battery each shift, all take time and manpower. These tasks are required per lift, per shift, every day, whether you execute these tasks in-house or contract out this work to a third-party company.

By switching to a lithium-ion power source, workers will be able to focus on more important tasks and will be much more productive each day.

Choosing Lithium-Ion Batteries For Your Forklift

While lead-acid batteries are often the traditional choice, the truth is that choosing to use lithium-ion batteries for your lift truck fleet may just be the best option overall. Be sure that you consider the advantages of using lithium-ion for your own lift trucks. Doing so will ensure your business is operating at maximum effectiveness.

Dozens of companies have already successfully switched their truck fleets to Li-ion and are enjoying the benefits. OneCharge offers over 550 models with a proprietary state-of-the-art battery management system to fit nearly any truck make and model. Moreover, OneCharge will customize a battery based on the lift truck application, be it a regular warehouse, food processing, freezer environment, or outdoor conditions.

ENGLISH

ENGLISH  简体中文

简体中文